Voided Slab System

Voided Slab Formwork System

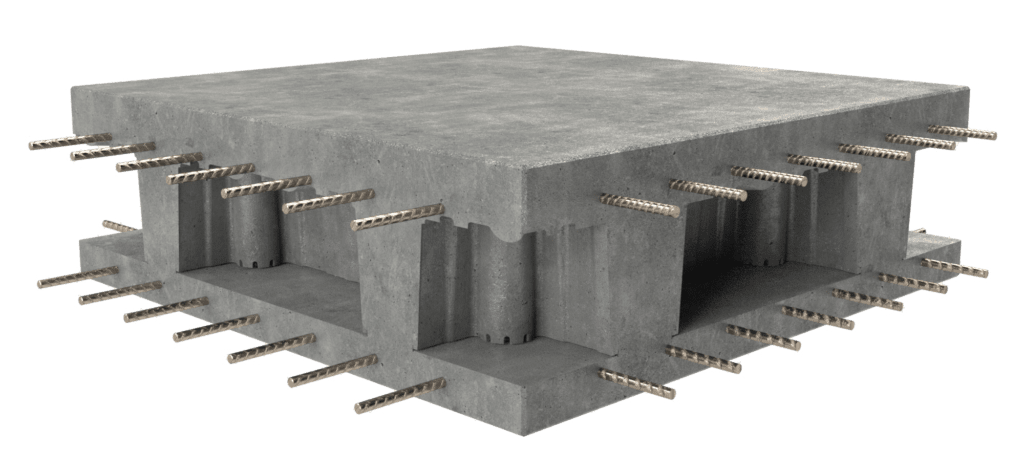

A reinforced concrete slab solution made from recycled plastics that enables large-span slabs to be easily passed without beams, creating voids within the slab to provide up to 25% cost savings in concrete and steel in building costs.

Voided slab formwork systems are designed to remain in the concrete, forming layers above and below the formwork. Thanks to this innovative approach, a rigid lattice or grid structure is created with flat plates on the top and bottom, created with only one concrete pour. This method results in a significant reduction in the amount of concrete and steel used, making it an economical and environmentally friendly option for construction.

The voided slab system is an excellent solution for creating large-span plates or plates that can carry large loads without using beams. Thanks to its lightweight design and modular structure, it can be applied quickly and easily. This structure provides designers with complete architectural freedom, allowing them to change static and geometric parameters as desired.

Voided Slab Advantages

Reduces load on the structural system thanks to its ability to support lightweight structures.

Reduces construction costs by up to 25% by reducing concrete requirements.

Reduces costs with less steel usage.

Saves time thanks to its ability to be installed faster and easier.

The scalability of the system allows it to be adapted for projects of different sizes.

Shows better performance for sound and thermal insulation.

Has features such as fire resistance, resistance to environmental effects and resistance to moisture.

Causes less harm to the environment by reducing the amount of XPS and EPS.

Shows better performance for water insulation.

Provides reduction in building height.

Suitable and economical for wider spans.

A suitable choice for thinner columns and foundations.

Provides high durability.

Because it is lighter than concrete slab systems, it provides the same strength with less material use in reinforced concrete structures.

Provides architectural design freedom and offers flexibility.

Makes it safer against earthquakes by reducing the weight of reinforced concrete structures.

Provides excellent sound insulation.

Provides space economy on the construction site as it can be nested.

Voided Slab Technical Details

| Height | Dimensions | Foot Height | Unit Volume | Pallet Dimensions | Pallet Pieces |

|---|---|---|---|---|---|

| H 10 cm | 52 x 52 cm | 0-7-8-9-10-11-12 cm | 0,0217 m³ | 110 x 110 x 247 cm | 720 pc |

| H 13 cm | 52 x 52 cm | 0-7-8-9-10-11-12 cm | 0,0289 m³ | 110 x 110 x 212 cm | 600 pc |

| H 16 cm | 52 x 52 cm | 0-7-8-9-10-11-12 cm | 0,0354 m³ | 110 x 110 x 254 cm | 440 pc |

| H 20 cm | 52 x 52 cm | 0-7-8-9-10-11-12 cm | 0,0439 m³ | 110 x 110 x 236 cm | 460 pc |

| H 23 cm | 52 x 52 cm | 0-7-8-9-10-11-12 cm | 0,0493 m³ | 110 x 110 x 253 cm | 440 pc |

| H 26 cm | 52 x 52 cm | 0-7-8-9-10-11-12 cm | 0,0550 m³ | 110 x 110 x 249 cm | 419 pc |

| H 29 cm | 52 x 52 cm | 0-7-8-9-10-11-12 cm | 0,0572 m³ | 110 x 110 x 256 cm | 398 pc |

| H 30 cm | 52 x 52 cm | 0-7-8-9-10-11-12 cm | 0,0643 m³ | 110 x 110 x 253 cm | 390 pc |

| H 33 cm | 52 x 52 cm | 0-7-8-9-10-11-12 cm | 0,0710 m³ | 110 x 110 x 247 cm | 382 pc |

| H 36 cm | 52 x 52 cm | 0-7-8-9-10-11-12 cm | 0,0792 m³ | 110 x 110 x 237 cm | 370 pc |

| H 40 cm | 52 x 52 cm | 0-7-8-9-10-11-12 cm | 0,0866 m³ | 110 x 110 x 256 cm | 360 pc |

Our Certificates

ISO 9001:2015

International standard for quality management systems. It defines the processes necessary to manage product and service quality, continuously improve and increase customer satisfaction.

ISO 14001:2015

International standard for environmental management systems. It defines the processes necessary to manage and reduce environmental impacts.

ISO 45001:2018

International standard for occupational health and safety management systems. It defines the processes necessary to manage occupational health and safety risks and ensure employee safety.

Installation

Formwork Preparation

First, the formwork into which the concrete will be poured is prepared and its supports are placed. The surface of the formwork is covered with wooden floors, making it ready for concrete pouring. Bottom reinforcement bars are placed in two vertical directions according to the design and a cage is prepared for top reinforcement.

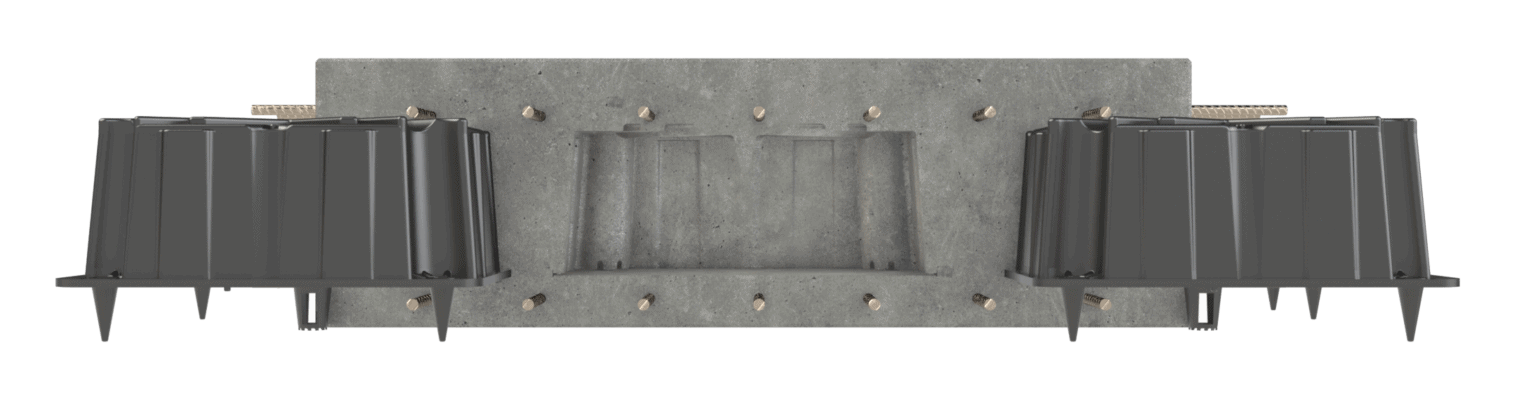

Voided Slab Formwork

For voided slab, the beam width is adjusted according to the specified dimensions in the static project. Thanks to the conical feet under the formwork, the voided slab formworks are raised from the surface to create the lower slab. If double or triple elements are used, these elements are assembled first.

Reinforcement Arrangement

Together with the top bars, the positioning of the reinforcement according to the design is completed, including shear and punching reinforcements.

Concrete Pouring

To prevent the surfaces of the formworks from floating, the pouring is carried out in two stages. First, an initial layer is poured as high as the conical foot height. This layer continues to be poured until the concrete hardens and becomes semi-fluid.

Continuation of Pouring

After the concrete pouring is adjusted appropriately, the pouring is restarted to completely cover the voided slab system. Then, the pouring is leveled in the traditional way.

Frequently Asked Questions

Paketleme Boyları

Geleneksel dolgu malzemelerinden çakıl ve toprak gibi veya polistiren (EPS), ile karşılaştırıldığında çok daha hafiftir.

1 tır = toprak veya çakıl

1 tır = EPS (polistren)

1 tır = gaz beton

1 tır = Boşluklu Döşeme Sistemi

Kalıplar üst üste istiflenebildiği için, şantiyede daha az depolama alanı gerektirir.